Proof

Proofs are pre-simulations of the later printing image which act as a foundation for content, technical and colour releases. Special proof processes with whose help errors and the smallest deviations can be discovered in each phase in the prepress process. This safeguards quality and saves both time and costs, because errors that are incorporated are double the burden in the advanced work process. A distinction is made between two classes of proofing processes: Soft proofs, which exist purely virtually on the screen in the form of PDFs or special soft proof systems and Hard proofs, which exist in the form of physical printouts.

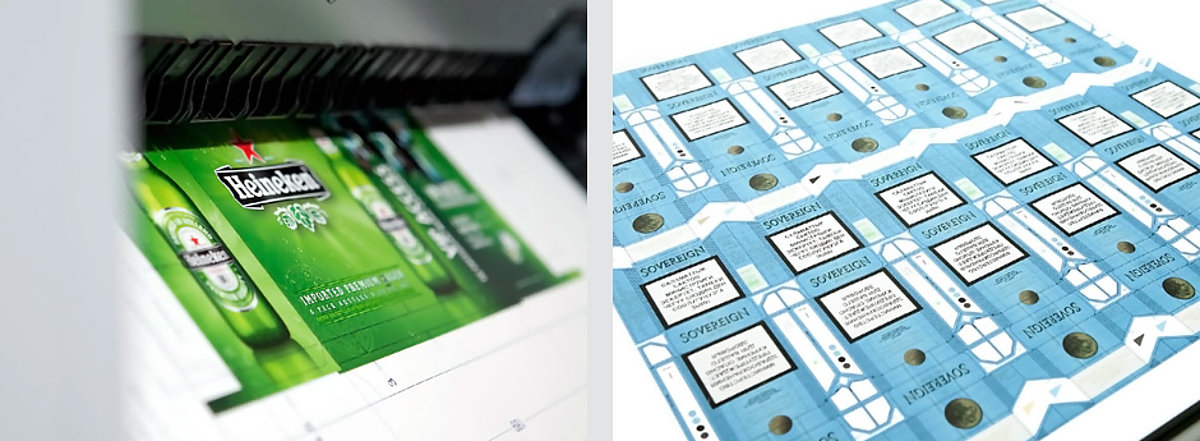

The target proof is created in the early phase of the prepress process, and as a rule this does not contain any printing specific adjustments yet. Following release by the client it becomes the binding model when compared with the contract proof and proof printing. At the end of colour separation in reproduction there is the contract proof, which already contains all printer-specific information. It guarantees the reliable implementation of the objectives agreed in the target proof. To produce a printing form a so-called form proof (also step & repeat proof) which represents the technical layout on the plate or cylinder is produced.

The big challenge when proofing in packaging printing is colour binding, as no industry standards exist for flexible packaging printing. This makes a standard reproduction impossible (Fingerprinting, Print Colour Management).