Gravure

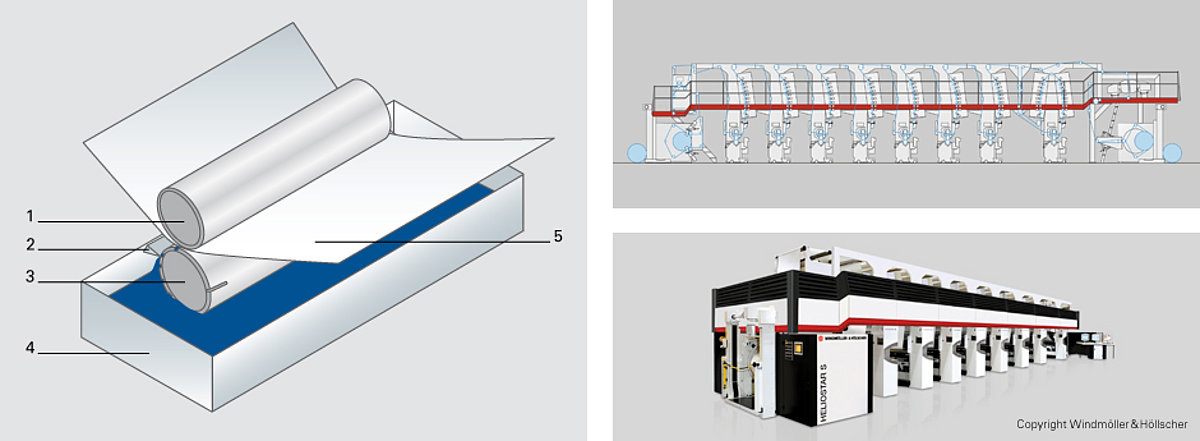

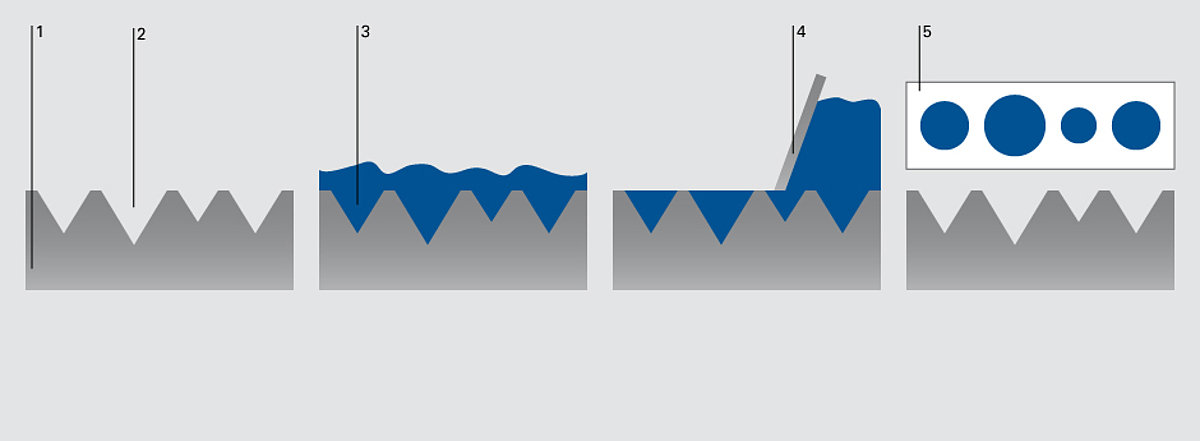

Gravure, also called rotogravure, developed from copperplate engraving. The direct printing process offers the highest printing quality and is used today in art reproduction as well as in the commercial printing sector. Rotogravure is used in particular for high and very high print runs, e.g. of catalogues and magazines. In contrast, sheet-fed gravure is reserved for more expensive and particularly high-quality print products. A gravure cylinder in whose surface the printing design is engraved acts as a printing form. A portion of the printing form dips into a tray with thin liquid printing ink. The ink is removed from the raised, non-printing surfaces with a doctor blade, similar to a steel ruler. Cell walls, which cover the cylinder like a grid shaped net, ensure the clean guidance of the doctor blade even over large surfaces to be printed. After the doctor blade wipe-off, the printing ink remains in the depths, the so-called cells, and is released through mechanical contact with the printing material.? Dark and lighter tones are created through more or less ink, i.e. through deep or less deep cells. Gravure is thus the only printing process where different thick ink layers and thus tonal values can be created inside a printing form. Gravure cylinders? are manufactured on a customised basis and are thus absolutely endless, which among other things explains their preferred use on flexible packaging materials. Printing fluctuations due to wear hardly exist in gravure.

Recognition characteristics: As the text and image have to be both screened in gravure, the so-called sawtooth effect on letters and line drawings is the most significant characteristic. The printing quality is good, the colours saturated and the photos are represented with the genuine colour.