Laser etching

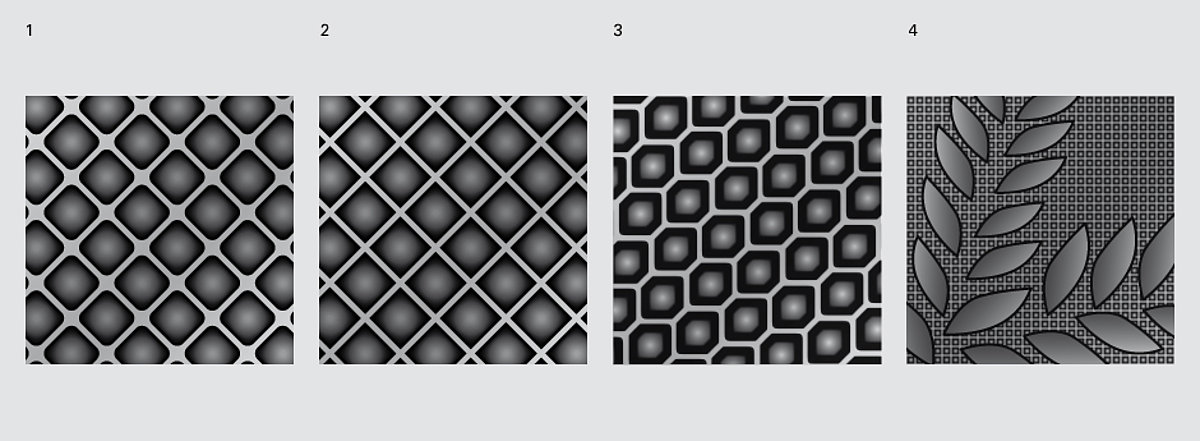

Laser etching is a traditional imaging process for gravure cylinders. Similarly to electro-mechanical engraving or laser engraving, the cylinder is copper-coated before etching. A further layer of UV sensitive lacquer covering with a thickness of 4µ – 10µ depending on the etching depth, protects the cylinder during the etching procedure at the axes and front sides. The corresponding image is transferred to the cylinder being coated by using a Digilas laser from 40 watt and with up to four beams. By etching with ferrous 3 chloride after the laser procedure, the cells are deepened and widened, without the covering layer dissolving in the process. The cylinder can be chromed after the covering layer is removed form the surface, front side and axes. The geometrical shape of the cell during etching is quadratic and screening ranges from a 70 screen to a 120 screen. In the case of special applications coarser screens (20) or also finer screens (160) (e.g. during security printing) can be used. The standard angular position (-> screen angle) in etching is 45°, but other angles are always possible. In contrast to direct laser, the Digilas Laser operates on a standard basis with several shots for a cell. As a result a large bandwidth is created in the cell geometry, e.g. cushion screen, honeycomb screen, special screen.

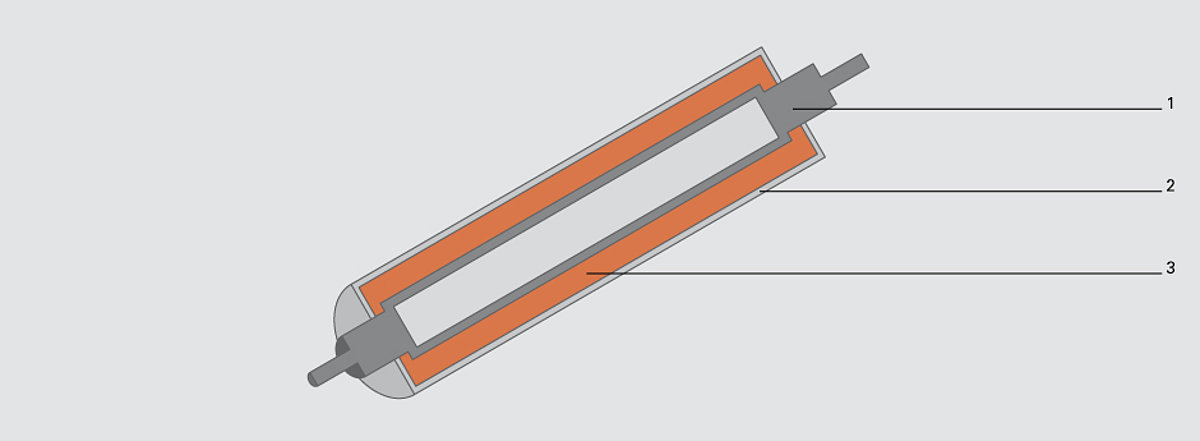

1 Steelbase 30mm, 2 Chrome 7 µ, 3 Copper 0,3 mm

2 Engraved letter (fine screen) with and without outline