Electro-mechanical engraving

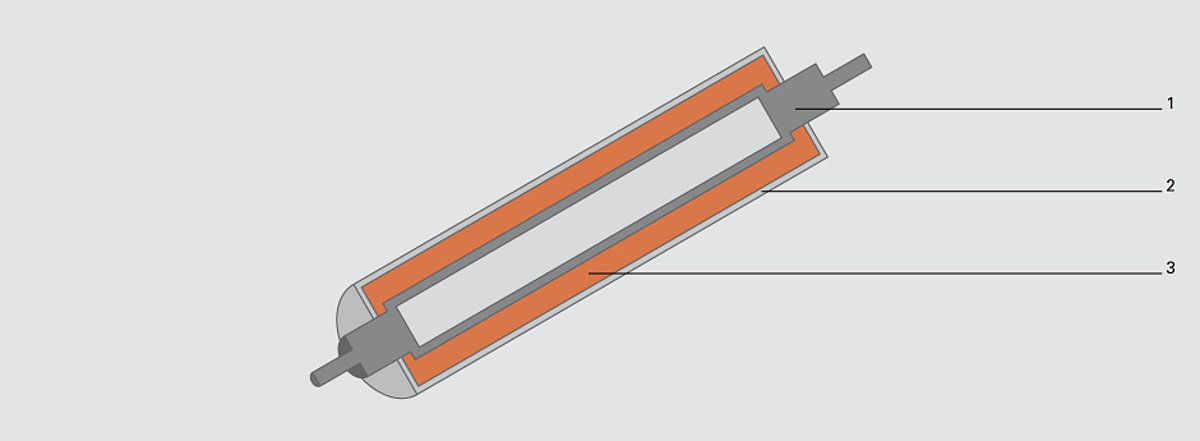

The basis for electro-mechanical engraving is a copper-coated steelbase with a 0.1 mm strong layer of gravure copper and special surface processing. The so-called cells are engraved in this surface with a diamond stylus. Depending on how fast the cylinder turns around its own axis, the cells are formed longer or more compactly. The diamond stylus is guided via an engraving system, which moves on a slide in parallel to the cylinder axis. To control the diamond stylus, the digital repro data is converted into electrical impulses. The darker the grey values, the deeper the insertion. Up to 12,000 cells can be engraved per second. After the gravure, the cylinder is chromed to achieve better durability. Practically endless identical printing results can be achieved.

1 Steelbase 30 mm, 2 Chrome 7 µ, 3 Copper 0,3 mm

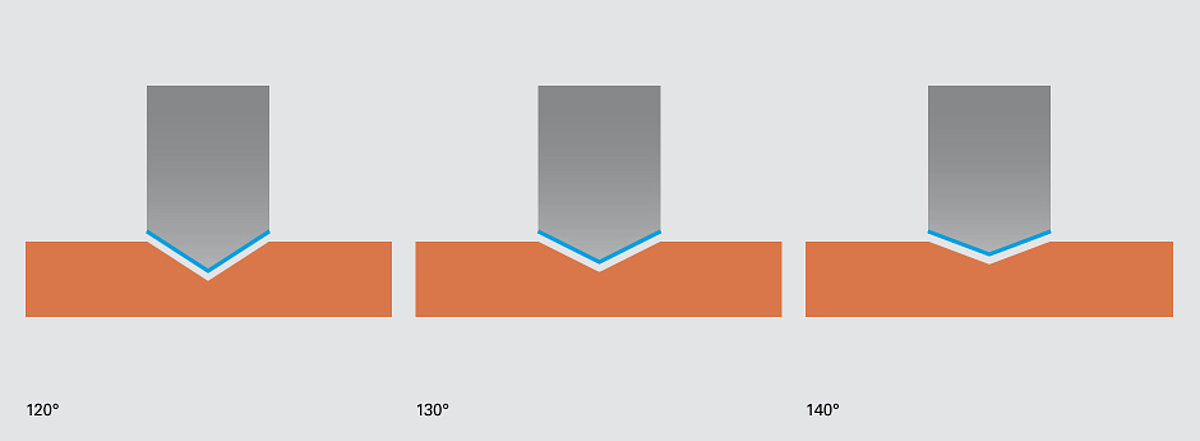

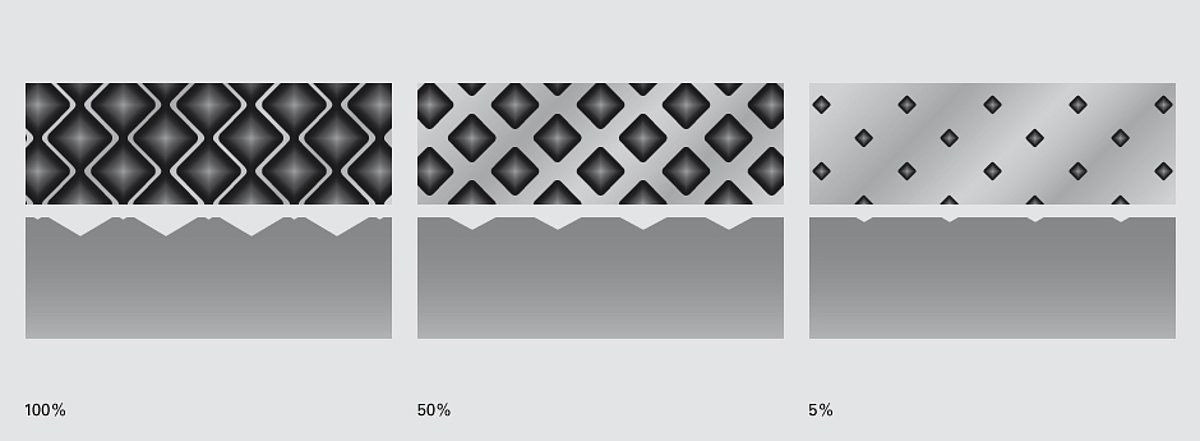

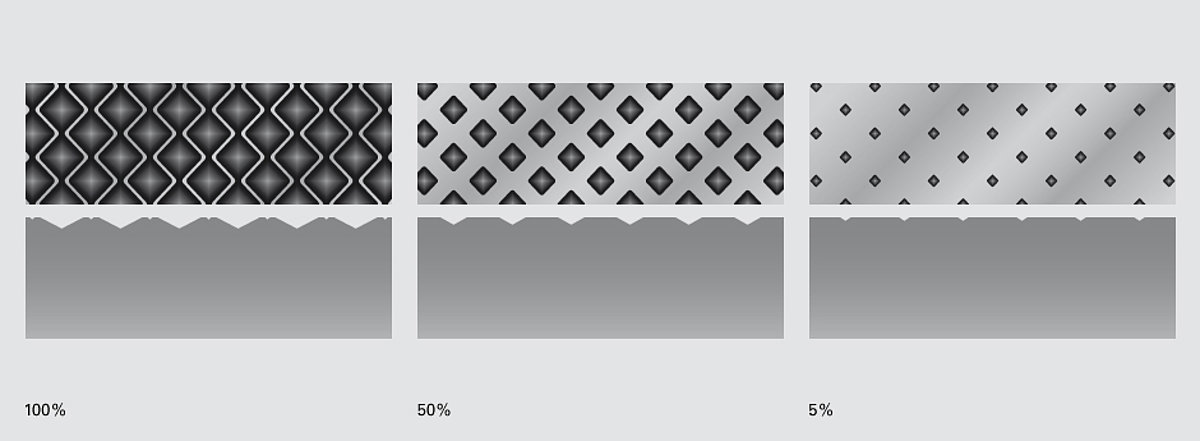

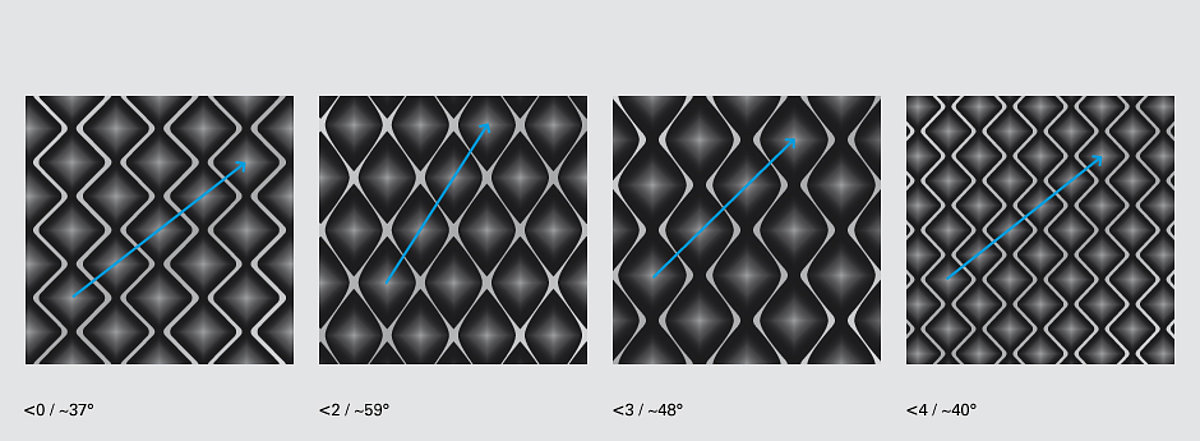

Cell form: half-autotypical (variable depth and cell opening)

Cell form: half-autotypical (variable depth and cell opening)

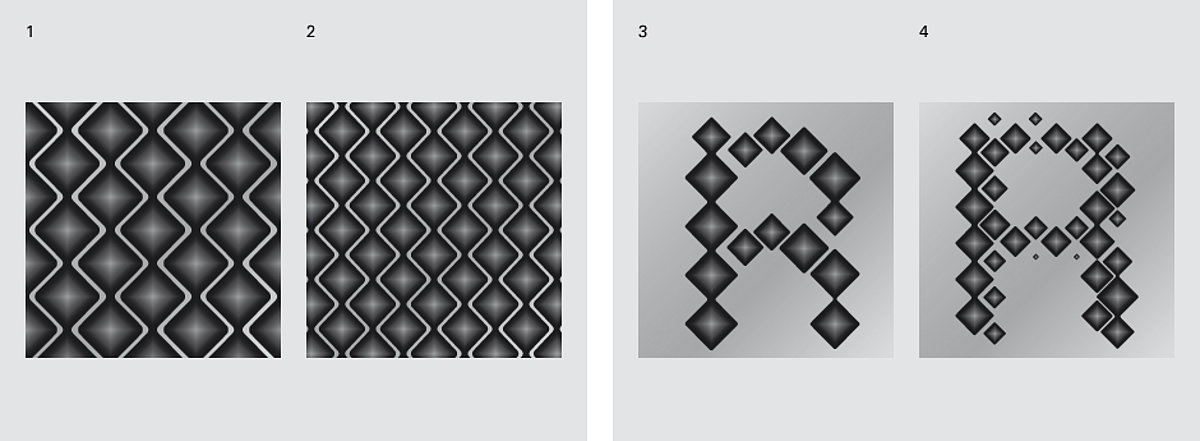

right: Engraved letter (fine screen)