Digital printing

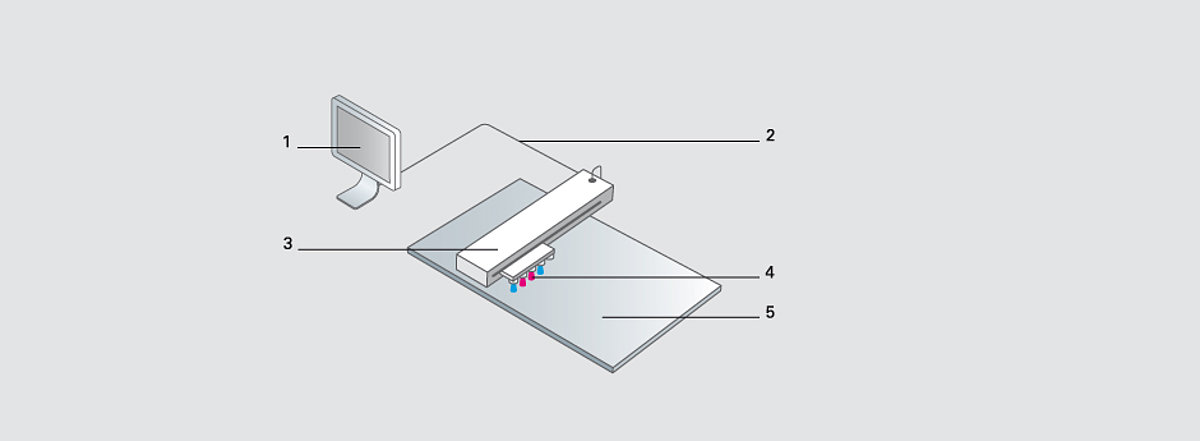

In contrast to gravure, flexographic and offset printing, digital printing is a printing process for which no static printing forme is required. Each sheet can be printed individually because the print image is transferred directly from the computer to the printer.

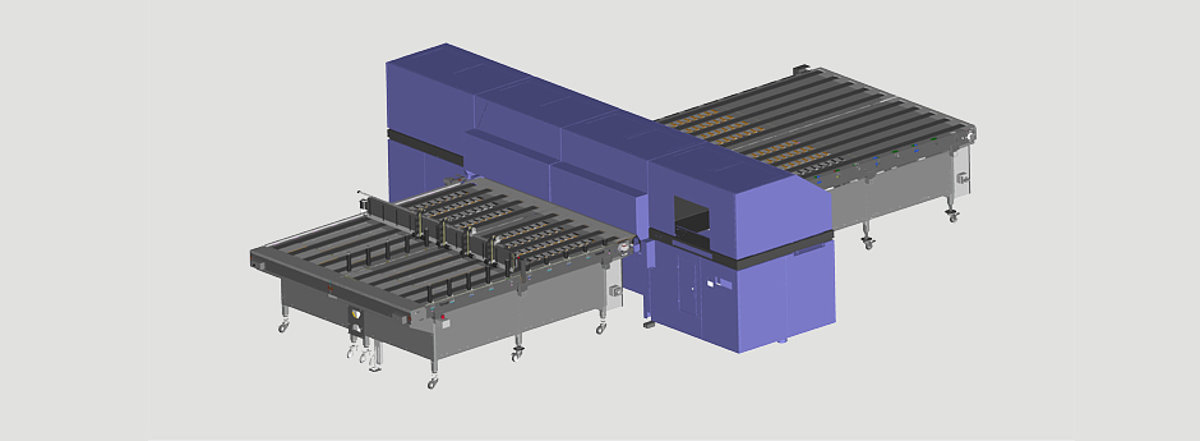

Conventional digital printing using inkjet or laser technology has become the standard in many industries. However, the use of digital printing technology for printing on large-area substrates with a certain material thickness is a relatively new trend which opens up completely new possibilities in, for example, the decor market. Whilst with direct printing, the print is applied to the substrate from a gravure cylinder via a rubber roller, with digital printing the printer prints directly onto the substrate. Printing is contactless so even deep places, such as grooves or open pores, can be coloured. The greatest advantage is that even the shortest of runs can be produced. The workpiece is really not customised until towards the end of the production process. The variety of decors and the flexibility of the printing process are almost endless. The decor can be changed without interrupting the production process because digital data transmission eliminates make-ready times.

Furthermore, in digital printing a higher resolution (max. 120l/cm) can be achieved compared with decor gravure printing (max. 70 l/cm). Even the colour space is much more extensive than printing with CMYK.