Flexo printing form

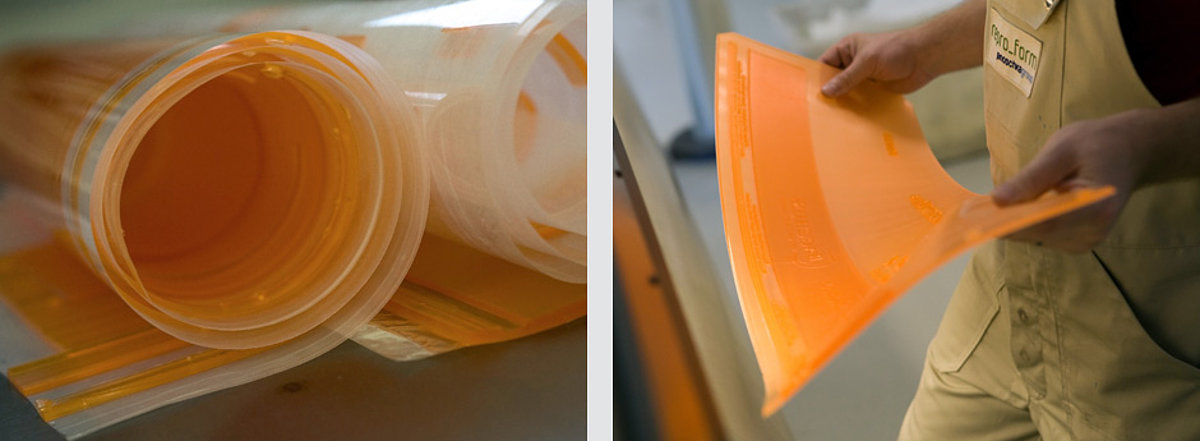

A distinction is made between two types of printing form in flexo printing. The printing plate is a flat printing form (usually a polymer plate), which is glued onto a basic cylinder. In contrast, a sleeve is a form shell with a photopolymer or elastomer surface, which is imaged. In comparison to an engraved elastomer full cylinder form, a sleeve can be installed and removed relatively easily and in contrast to a glued-on plate has a high position tolerance.

All flexo printing forms are made of a flexible material such as elastomer (rubber) or photopolymer. The photopolymer printing form is imaged directly using a laser and then exposed with UV light. Non-printing features are washed out in the subsequent washing process. Residual solvents from the washing process evaporate during the concluding drying of the printing form. The manufactured printing plates are mounted on a basic cylinder with adhesive bands. The compressibility of the foils and the plate strength is decisive for the print result, as both influence the ink transfer. Thick plates and non-compressible foils are therefore used for flat surface printing, whereas thinner plates and compressible foils are more suited to raster printing. Thick plates are used for strong printing substrates (e.g. corrugated board), as these can offset variations in the strength of the printing material.

Gap and seamless printing forms for endless printing, so-called photopolymer endless sleeves, can also be produced through the use of special processes. Elastomer (rubber) rotary endless printing forms are produced by direct laser engraving. The laser accordingly ‘removes’ the rubber directly in the imaging process.