Embossing

The process of embossing is used in the industrial manufacture of very different surface structures. In principle, there are possibilities to produce structures flat or on a rotary basis. Examples of embossing applications from artificial leather surfaces in vehicle construction via the structuring of imitation wood, wallpapers and paper napkins up to a cigarette package. Embossing for refinement is particularly important for printing products in the packaging sector.

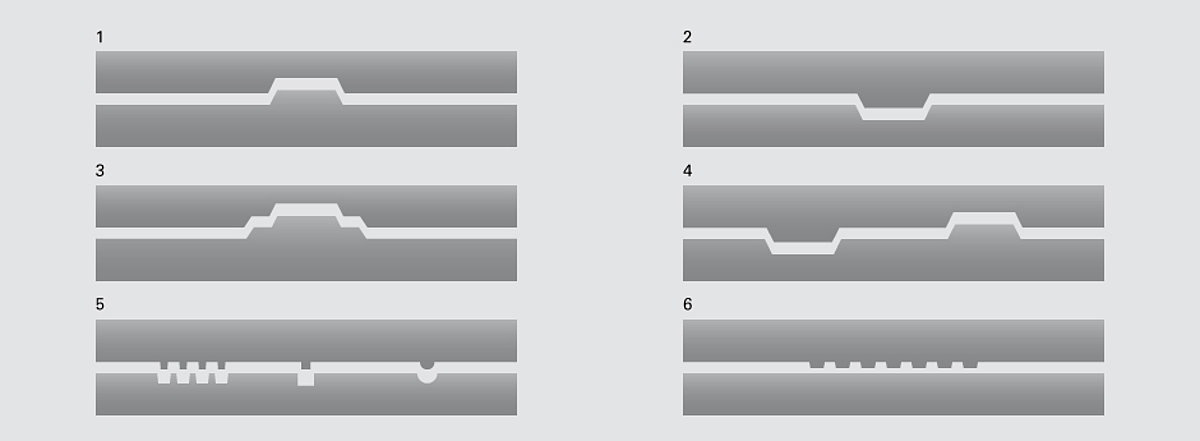

A distinction is made between high embossing / debossing and blind embossing. Whereas a set of two types of cylinders which fit into each other exactly is produced during embossing and debossing, with blind embossing there is only one embossing cylinder, which pushes the printing substrate against a flat cylinder. The embossing is produced here by compression and not through plastic deformation. Two other embossing options include hot foil stamping, which builds up an effect foil via heated elements and on the other cold foil stamping whereby an adhesive lacquer is printed on the substrate and then an effect foil is transferred to a printing lacquer.