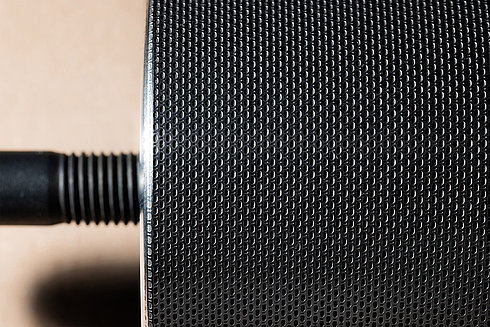

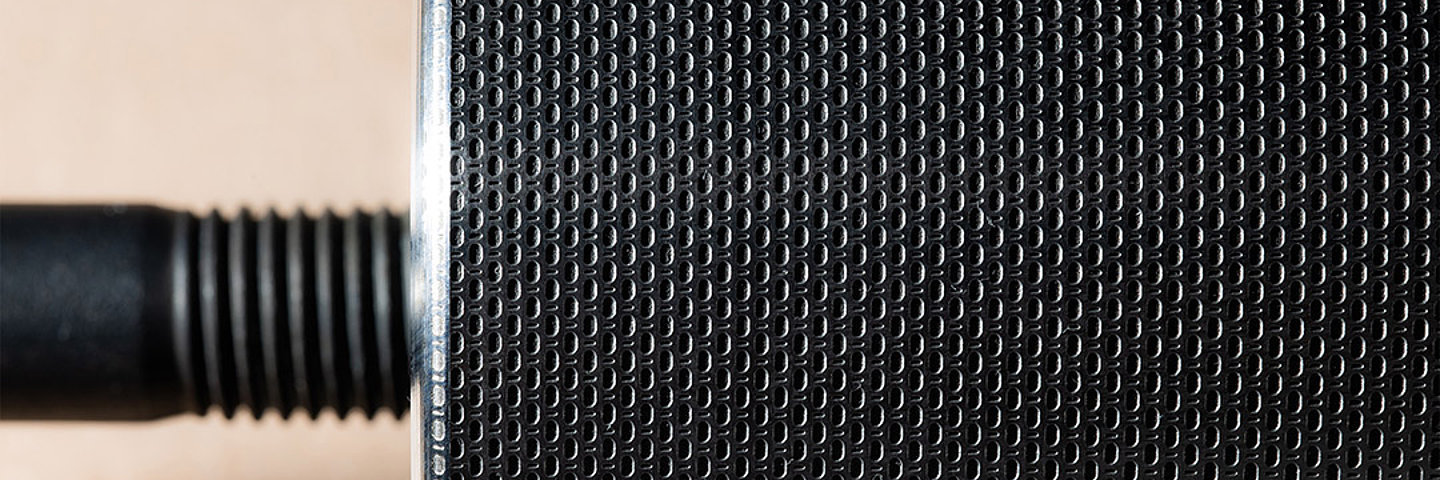

Stainless steel used for building façades and cladding for lifts and surfaces at supermarket checkouts is embellished with embossing, lending the material additional visual as well as functional qualities. The architects’ goal, in addition to stability and durability, is to achieve light refraction through embossing, giving the building a perfect and bright, gleaming surface.

Janoschka has been supplying embossing tools for different markets and applications for over 20 years. In addition to pattern rollers for materials including tissue, yoghurt pot lids and cardboard packaging, we also produce embossing tools for stainless steel, where linen and honeycomb structures as well as irregular patterns are used.

The embossed, decorative and timeless patterns add a new dimension to any surface and make the design more sustainable, not only in architecture, but in many other areas as well. We come across embossed components made from stainless steel on a daily basis at the supermarket checkout, where items are transported from the conveyor belt onto the corrugated section, as well as in lifts with distinctive cladding. Embossing enhances material with additional characteristics and qualities, making it more resistant or non-slip, more stable, low-maintenance and easier to clean.

A wide variety of materials can be enhanced with embossing, from carton and paper to plastics and composite films to non-wovens and tissue, as well as steel components. Our embossing expertise allows us to fully exploit the potential of this technology, whilst meeting market demand for effective surfaces, quality and design.

Make buildings shine

Your contact